Almost all DIY or similar works often require the placement/removal of nuts & bolts. The problem arises when the operation gets in a tight/narrow space or awkward angles. Also, there are several issues with nuts/bolts/screws with a too tightly wound.

And the first tool to come in mind to tackle the issues is a wrench. When every other wrench fails to handle the situation, you can rely on impact wrenches. It’s easy to operate & one obvious favorite to pros.

Using an impact wrench is no daunting task. But without knowing how does an impact wrench works, your expertise with it leaves one certain gap. Therefore, it’s of utmost importance to realize –

How does an impact wrench works-

Types of Impact Wrench:

Before knowing the functionality, it’s important to know the current wrench types. Different classes slightly vary in the overall mechanism & therefore, the efficiency. In particular, there are three types available when it comes to impact wrench.

- Corded Impact Wrench: The impact wrenches here have cords for electricity connection. Electric ones are undeniably efficient, especially for professionals. When you have to deal with tons of nuts every single day, there’s no alternative to electricity-powered wrenches. It’s also incredibly consistent without generating much noise.

- Cordless Impact Wrench: For outdoor activity, you can certainly count on cordless ones. Though it requires electricity, the power comes from a rechargeable battery. Without any power restriction, the cordless ones can fasten or loosen the nuts for long. The drawback is its loud noise which may require an additional purchase of earplugs.

- Air Impact Wrench: With no electricity or battery, this is one eco-friendly option. Driven by cool air, the wrench offers premium performance over a small body-mass ratio. The efficiency is relatively low in comparison to others, yet it gives a satisfactory output. It’s quite suitable for outdoor tasks in remote areas. Part replacement is inexpensive, making the wrench a more durable tool.

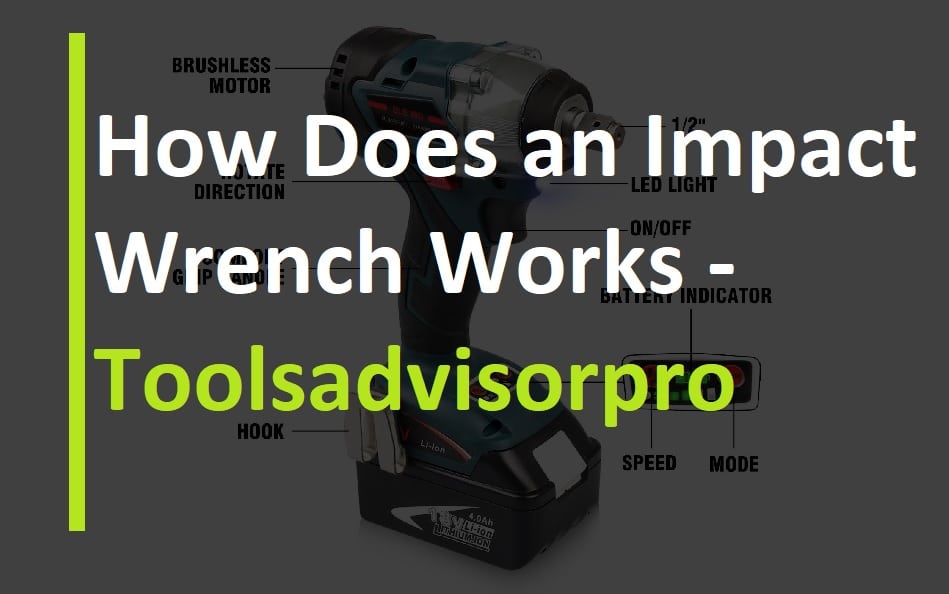

Basic Parts of Impact Wrench:

To understand the functionality, you’ll have to know the basic assembly well. Each important part has specific tasks regarding proper system workability.

There comes one steel-housing inside the device. In general, the housing is of high-grade stainless steel. Its function is to generate & hold the centrifugal force.

Rotor blades inside the rotor are of quality metal, generally steel. Using the generated airflow, the blades induce consistent movement. This later directly initiates the centrifugal forces.

Rear coverlets the airflow through to make contact with the rotor. Meanwhile, the anvil at the rotor center uses the motor rotation to generate the airflow.

Fundamental Mechanism of Impact Wrench:

All types of impact wrenches feature an integrated motor. With other parts, there exists a solid rotating mass. Through the designated power (electricity, battery or compressed air), the motor gets activated.

The basic difference lies here in accordance with wrench types. Electrical ones give a direct power activation where it comes from the battery for cordless ones. With the AC current, the rotor attains kinetic energy to trigger movement.

But the pneumatic (air-driven) wrench bears the most significant difference. It features a tank/container of compressed air to activate the motor.

The rotation creates a full airflow to motorize the connector. Using the hole, the generated airflow reaches the rear plate. The rear plate allows the flow to get into the rotor cylinder to make contact with rotor blades.

With gravity, the blades start to move. There are generally 6 blades centering the anvil. The combination of consistent flow & moving rotor induces centrifugal force or torque. Following the induced torque, there occurs a pressure circulation inside the housing.

The resulting motion takes place in an intensely twisting pattern. Producing shorter bursts (about 5 seconds or so), it lets you accomplish the task. This is the motion that drives the recalcitrant lug nuts.

Maintaining consistency, the wrench keeps generating continuous bursts. The system handles the job through the short, strong bursts using the twisting fastener. Using the movement, it becomes simple to tighten or loosen the targeted nuts.

To improve functionality, it requires more operational torque. With further pressure from the motor, the system can induce extra force. Through the additional force, the wrench initiates higher twisting power for greater torque.

Both electricity & battery can’t go further exceeding their specified rating.

Therefore, it’s somewhat difficult to achieve extra torque in those wrenches. But air-driven impact wrench got no such restriction. You can push it quite further to attain a greater amount of torque.

Also Read: How to use an impact wrench

Verdict

Bringing you additional force/torque, an impact wrench can easily budge almost anything. Without knowing how does an impact wrench works, you can’t make the best use. We covered the basics here in simple terms to make you understand. It’ll help you to use, handle & maintain the tool with greater care.

Check out everything to know about automotive in our guides.